Mytra has been operating behind the scenes since its founding in May 2022, with a mission to rethink warehouse automation. This startup, founded by automotive veterans from EV firms like Tesla and Rivian, brings a solid pedigree to the table.

Warehouse and fulfillment automation has become a hot category since the pandemic disrupted the global supply chain in ways still being felt. It’s a highly competitive space with big names like Amazon, Locus, and Zebra/Fetch making significant progress and generating interest in the bipedal humanoid form factor.

Even as the world recovers post-pandemic, labor shortages remain a significant challenge for the industry, as with many others. There is still ample opportunity for new players to make an impact. Estimates suggest that only between 5% and 10% of global warehouses are meaningfully automated.

Like many others, Mytra co-founder and CEO Chris Walti discovered automation’s shortcomings firsthand. He was previously at Tesla, where encountering challenges is common. Walti spent seven years at the carmaker, starting in engineering, then mobile robotics, and ultimately as the senior manager/lead for what would become Optimus.

He describes his journey through Tesla as an ongoing cycle of seeking solutions, finding that nothing on the market met the company’s specific needs, and then building those solutions themselves. This began with autonomous mobile robot (AMR) solutions.

“I was pulled into manufacturing and automation through the Model 3 ramp,” Walti told TechCrunch. “Tesla was struggling to get our automation systems up and running, so we ended up setting up a manual warehouse as a pressure release valve for the manufacturing system. About six months later, they were like, ‘Can you just take over the automation system that’s causing a lot of these challenges?’”

Among the industry shortcomings that emerged for Tesla’s specific needs was an inability to find AMRs capable of moving payloads as heavy as 3,000 pounds. Those are the sorts of demands encountered when manufacturing cars. So the team began building their own solutions in-house.

“And then Elon [Musk] was like, ‘We should build a humanoid,’” Walti said. “My team was tapped to lead that. I led the internal hiring effort for that team. Everything you saw on AI Day was a product of those efforts.” He added that, “at some point, [Optimus] became the number one effort in the company. It ended up not really being a fit for what I wanted to do.”

Walti remains optimistic about the long-term impact of humanoid robots across various sectors but noted that he “think[s] it’s going to be a while before humanoids are truly moving the needle on a production floor.”

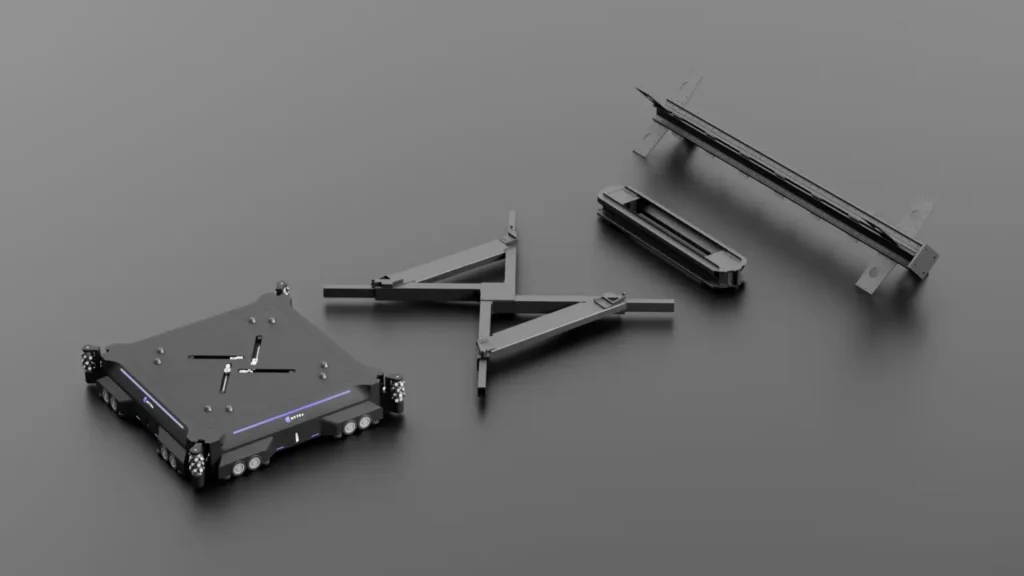

Mytra’s solution shares a lot of common DNA with vertical robotic storage solutions produced by companies like AutoStore. Two primary differentiators between the startup and existing solutions, according to Walti, are its ability to manage heavy payloads.

“There are literally trillions of different ways that I can move one of these pallets or bookshelves from point A to point B within the system,” he explained. “Which is fundamentally unique. This is the most kinematically free system that has been conceived.”

Despite maintaining stealth until now, Mytra has already attracted interest from big names. The startup has a pilot with grocery giant Albertsons, along with “another half-dozen Fortune 50 customers that are in varying stages in the pipeline.”

Mytra also recently closed a $50 million Series B, bringing its total funding up to $78 million. Investors include Greenoaks and Eclipse.